The SINUMERIK ONE touchscreen uses the same gestures as used on the most popular smart phones and tablets.

No matter what programming style you find comfortable, you can use it on the SINUMERIK ONE.

Shopmill & Shopturn = True conversational programming that uses shop language to define your entire part. Edit in the same conversational format that you programmed in. Canned cycles make programming fill-in-the-blanks easy.

Easily transition between programming, manual and automatic CNC operation screens.

Easy Program Restart even if the stop is unplanned, like the press of an e-stop or a power outage.

Tool names make it easy to recognize tools available and assign sister tools.

Powerful DRO (manual mode) Routines enable you to set up your parts easily with access to powerful functions:

Animated elements within programming shows you what the choices look like when they are selected.

Easy building of programs allows you to combine G-code and conversational programming in the same program.

Advanced program summary — even your largest programs can be scanned with ease. Graphics for subprograms and other elements.

Tool Tips as you hover over a field give you a quick description of what goes there. Easy building of programs allows you to combine G-code and conversational programming in the same program.

Handwheel Run takes the anxiety out of running that first part. Run the program with feedrate controlled by you turning the handwheel.

Softkeys guide you as you work.

Consistent soft key placement and screen organization eliminate confusion as you navigate between screen operations.

Dynamic images change with the selection of the field.

The Information key displays instructions for the operation you are on.

Instant simulations as you program alerts you to problems while the inputs are still fresh on mind.

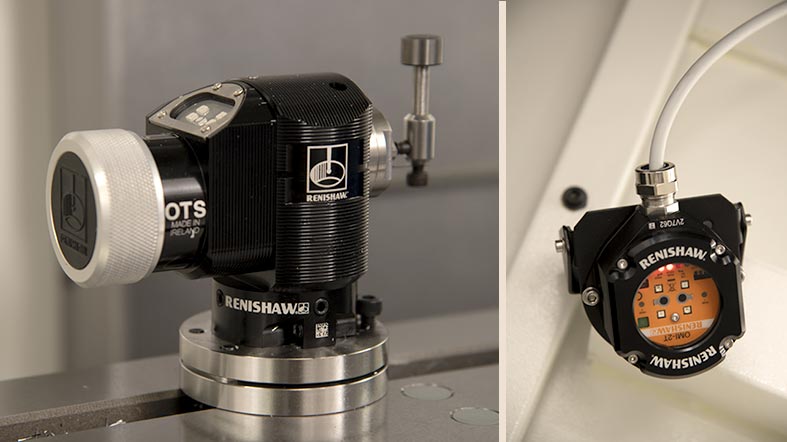

The native cycles of the SINUMERIK ONE work with many brands of probe, or even with a manual edge finder.

Part Measurement routines for part alignments in set-up and in-process measurement to check part dimensions.

Tool probes for quick, accurate set ups loads the tool data directly into the Tool Table.

With the TRAK VMCsi you can achieve amazing finishes with a minimal amount of set up and programming.

Optional Advanced Surface and Top Surface are both advanced algorithms that analyze the program and converts points to splines to create a superior toolpath that is processed smoothly through the SINUMERIK ONE run engine.

The rigid construction of the VMCsi makes it a machine you can really push and the responsive servo motors and advanced motion control of the SINUMERIK ONE provides excellent acceleration and control of jerk.

Top Surface algorithm puts the trade-off in your hands. Turn on Smoothing for better surfaces. Leave it off for extra speed.

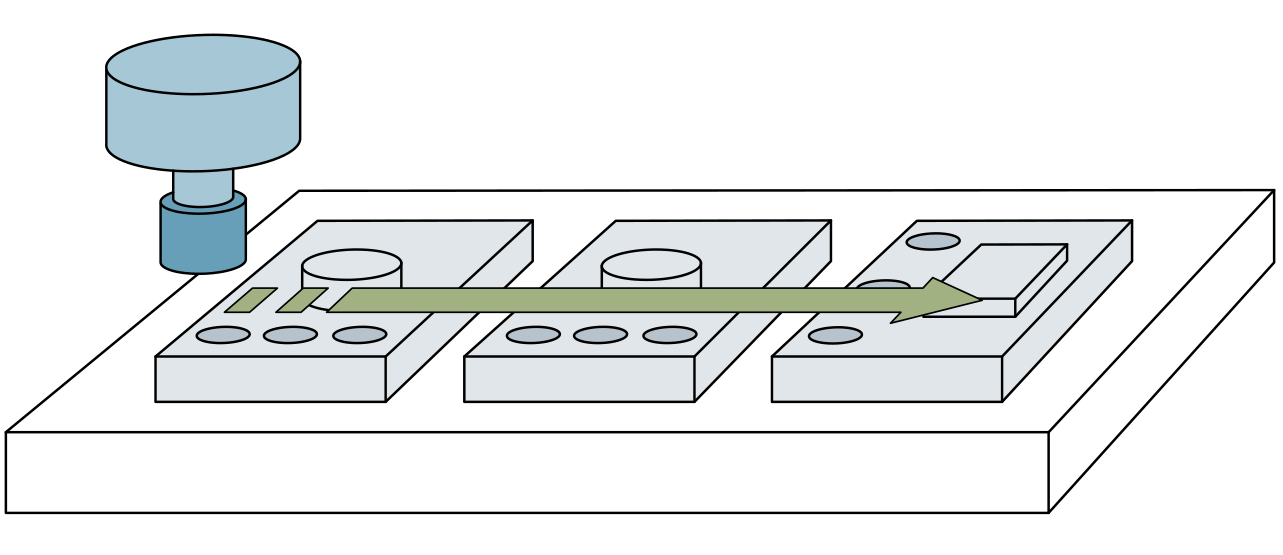

When running multiple fixtures, the SINUMERIK ONE will optimize your tool configurations for productivity by using the same tools and operations on different fixtures, even when different part programs are being machined at the same time. Ideal for production machining of identical or even different parts.

RTAC (Real Time Adaptive Feedrate Control) is Artificial Intelligence working for you! With RTAC the SINUMERIK ONE monitors the spindle load of the machine and automatically adjusts the feedrate to its optimal level during each operation. The SINUMERIK ONE makes adjustments as it “learns” the part – resulting in more parts with shorter machining time.

Nothing is more productive than running unattended—as long as the set ups are not excessive and the parts come out good. The SINUMERIK ONE has the features you need for both.

Simulations that help you visualize and adjust your programs precisely before you set up. Integrated Measurement Cycles that check the parts as the program is running. Sister tools that will automatically replace a cutter according to your instructions.

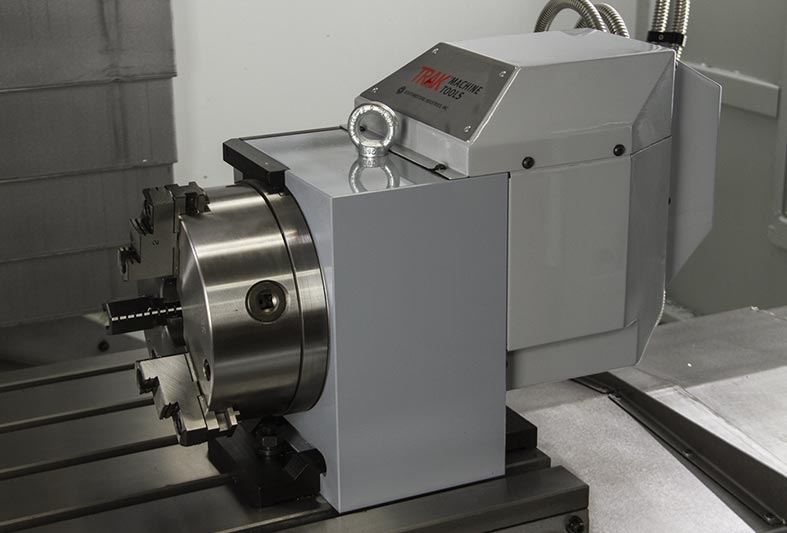

The TRAK 4th axis system provides full control of 4th axis machining through the Siemens SINUMERIK ONE CNC. The system can also be used as an indexer.

The powerful TRACYL software of the SINUMERIK ONE wraps a 2D shape around a cylinder, enabling you to program features onto a cylinder such as pockets and engraving.