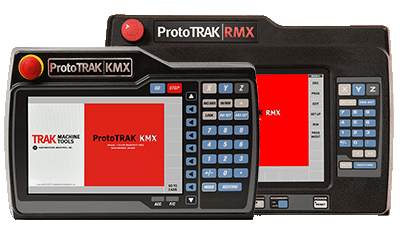

There is nothing like a ProtoTRAK for usability and the ProtoTRAK RMX goes beyond with productivity features that are not found anywhere else. Our 40 years of experience serving machinists in small lot milling applications have led us to a CNC that is simply amazing.

The power and flexibility of this latest generation CNC provide the best ever combination of control and machine for short run production and toolroom work. All in a system that is easy to use and as familiar as any ProtoTRAK.

The ProtoTRAK® KMX is the best CNC TRAK has ever made for knee mill applications. With the advanced technology, power and flexibility of the KMX, you can accomplish anything from quick manual jobs to complex profiling.

Both models use a quill drive for 3-axis machining. Manual quill control is accomplished with electronic handwheels. For most 3-axis machining applications however, we highly recommend our TRAK Bed Mills.

| All Models | |||

|---|---|---|---|

| Table Size | 10″ x 50″ | ||

| T-Slots (Number x Width) | 3 x .625″ x 3″ | ||

| Table Travel | 32″ | ||

| Saddle Travel | 16″ | ||

| Knee Travel | 16″ | ||

| Maximum Quill Travel | 5″ | ||

| Quill Diameter | 3.375″ | ||

| Spindle Taper | R8 | ||

| Spindle Speed Range RPM |

K3KMX (without Spindle Control): 60-500, 600-4200 K3RMX (with Spindle Control): 40-600, 300-5000 |

||

| Head Tilt | 45° forward and back, 90° left and right | ||

| Quill Feeds per Revolution of Spindle | 0.0015/0.003/0.006″ | ||

| Spindle Motor HP | 3 HP | ||

| Power Requirements - Control |

K3KMX (without Spindle Control): 110V, 1P, 10A K3RMX (with Spindle Control): 110V, 1P, 8A |

||

| Power Requirements - Machine |

K3KMX (without Spindle Control): 208/480V, 3P, 8.5/4.25A K3RMX (with Spindle Control): 208V, 3P, 11A |

||

| Maximum Weight of Workpiece | 850 lbs | ||

| Weight Net |

K3KMX: 2,800 lbs K3RMX: 2,816 lbs |

||

| Dimensions |

K3KMX: 78″ (length) x 103″ (width) x 87″ (height) K3RMX: 78″ (length) x 103″ (width) x 92″ (height) |

||

| Rapid Speeds | 100 IPM X, Y | ||

| Way Surface Type | Dovetail X/Z, Square Y | ||