| TRAK TC2 | |

|---|---|

Capacity |

|

| Maximum Swing | 12″ |

| Maximum Turning Diameter | 8″ |

| Maximum Turning Length (Z Axis Travel) | 11″ |

| X-Axis Travel | 7.5″ (direct drive with brake) |

| Z-Axis Travel | 11.4″ (direct drive) |

| Oil Pump - Way Lubrication | 2 liters |

| Rapid Speeds | 600 IPM on Z Axis 300 IPM on X Axis |

| Air Requirements | 90 PSI |

Headstock |

|

| Spindle Nose | A2-5 |

| Spindle Through Hole | 2.4″ - manual chuck option 2.047″ - hydraulic chuck option |

| Chuck Diameter | 8″ - manual chuck option 6″ - hydraulic chuck option |

| Drawtube Thread | M60 x 2 mm |

| Spindle Lubrication | Grease |

| Spindle Dia At Front Bearing | 100 mm |

| Number Of Bearings | 4 |

| Horsepower | 7.5 HP |

| Number of Speeds or Ranges | 1 |

| Spindle Speed Range RPM | 50-2500 - low speed, high torque 50-4000 - high speed spindle option |

| Spindle Motor Brake | Dynamic |

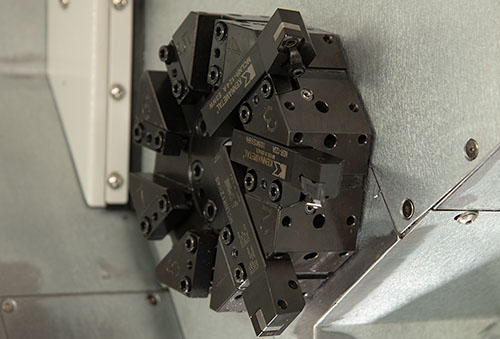

Turret |

|

| Turret Type | Bolt on |

| Number of Tools | 8 Stations |

| Turning Tool Shank Dimensions | 0.75″ x 0.75″ |

| Maximum Boring Bar Diameter | 1.25″ |

| Turret Index/Clamping Method | Servo motor/pneumatic |

Power Requirements - Machine |

|

| Voltage | 208V 480V with transformer option |

| Amps Full Load Current | 42A (208V) 25A (480V) |

| Phase/Hz | 3/60 |

Dimensions |

|

| Net (L x W x H), lbs. | 80.4″ x 36.5″ x 75.7″, 3,087 lbs 3,370 lbs with hydraulic chuck option (+283 lbs) |

| Shipping (L x W x H), lbs. | 85″ x 39″ x 87″, 3,200 lbs 3,800 lbs with hydraulic chuck option (+283 lbs) |

Coolant |

|

| Coolant Pump Motor HP* | 1/8 HP |

| Coolant Reservoir Capacity | 15.8 gal |