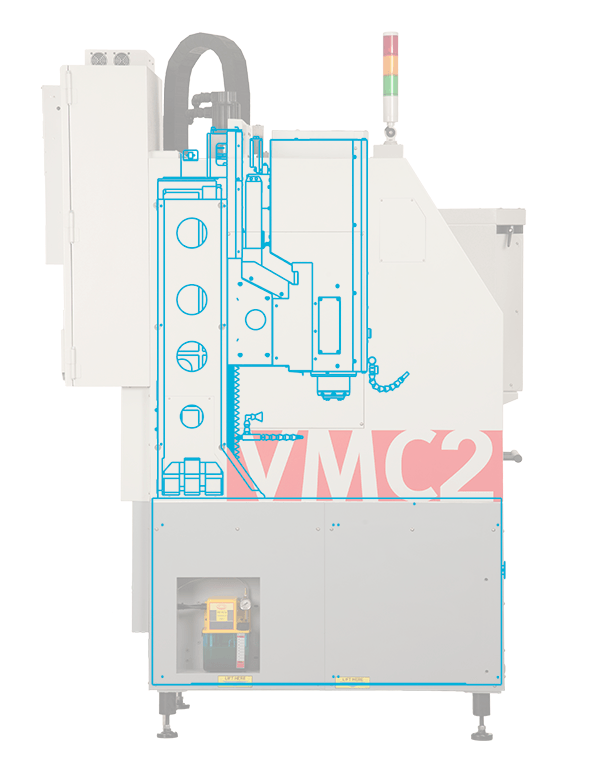

| TRAK VMC2 | |

|---|---|

| Table size | 18″ x 15″ |

| T-slots (number x width x pitch) | 4 x 0.629″ x 2.480″ (4 x 16 mm x 63 mm) |

| Travel (X, Y, Z axis) with soft limits | 14″ x 12″ x 17″ |

| Rapid traverse X, Y, Z | 400 IPM in Toolroom Ops 600 IPM in Production Ops |

| Spindle taper | 30 Taper |

| Spindle speed range - Production Ops | 50 - 10,000 RPM |

| Spindle speed range - Toolroom Ops | 50 - 5,000 RPM |

| Spindle nose diameter | 2.2″ |

| Tool clamping force (90 psi) | 850 - 1,000 lbs |

| Tool holder type | BT 30 |

| ATC tool capacity | 8 |

| Maximum tool weight (incl. holder) | 8 lbs |

| Maximum tool diameter | 2″ |

| Tool carrier speed | 1.2 - 1.4 sec from front to back |

| Tool selection system | Shortest path |

| Spindle motor HP - peak | 4.5 HP |

| Spindle motor HP - continuous | 3 HP |

| Power requirements | 208V (208-240V is acceptable), 3P, 30A 480V with transformer options (440-520V is acceptable), 3P, 15A |

| Maximum weight of workpiece | 500 lbs |

| Height of table from bottom of bed*** | 34″ |

| Min. spindle nose to table distance **** | 2.75″ |

| Max. spindle nose to table distance **** | 20.25″ |

| Spindle center to spindle head casting face | 15.7″ |

| Min. machine height *** | 93″ |

| Min. machine height to fit through doorway ** | 93″ |

| Max. machine height (head all the way up) *** | 101.5″ |

| Length (pendant enclosure rotated at 90°) | 88.25″ |

| Overall length of machine with electrical cabinet fully open 180° and pendant enclosure rotated 90° | 113.5″ |

| Footprint of machine (width x length) | 30.5″ x 52″ |

| Weight net / shipping (lbs) | 2,825 / 3,175 |

| Coolant capacity | 15 gal |

| Coolant pump power | 1/4 HP |

| Air - CFM (at 90 psi), SCFM | 2.5 CFM, 18 SCFM |

| Air quality | Air dried/water separator upstream of VMC |

| Lubrication pump capacity | 2 liter |

The ProtoTRAK RMX gives you powerful capability not found anywhere else. You’ll be amazed at how easy a capable CNC can be.

The uncluttered control panel features a keyed switch to help you assure that only qualified machinists can run the machine in Toolroom Ops.

The MTConnect option allows you to network machines, through either the ProtoTRAK’s ethernet connection or a USB Wi-Fi adapter, enabling you users to collect machine data in your shop.

MTConnect provides a standard structure for data across all your machines to eliminate confusion between proprietary formats. You can monitor machine status, receive notifications and analyze data throughout your machines’ history.