Machinists love to use ProtoTRAKs and it is no wonder. You get the automation you need to be efficient in an elegant interface that is easy to learn and use. At the same time it provides you with the manual capability that you need for so many things you do in a day.

The Electronic Handwheels give you power and convenient operation. Automatic Taper and Radius features give you simultaneous X/Z operation without CNC programming and setup.

Every operation of the ProtoTRAK RLX, including part programming, is configured for the shop floor. Instructions in plain English and conversational programming bring advanced capability to you right where the chips are cut.

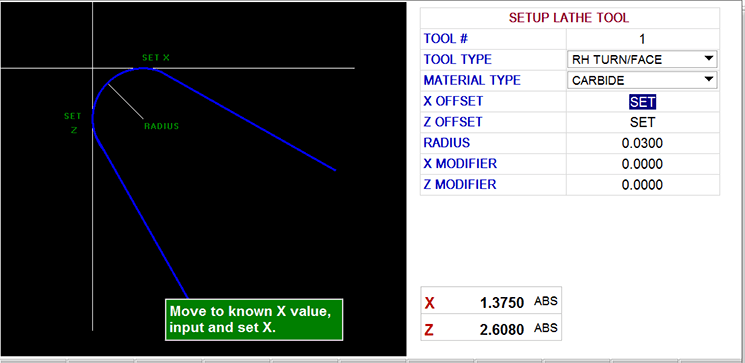

Precise tool setting is easy with graphics and prompts to guide you. Choose the tool type and the appropriate icon will show you where to touch your tools.

Picture this: you’ve written the program. Looked at the toolpath. Everything looks good, so you turn on the spindle and start to run.

But...you have TRAKing. So before you press the GO button you press TRAKing and then grab the handwheels. Talk about being in control! As you crank, the ProtoTRAK runs the program X and Z. You move the feed fast or slow. You can go forward or backward through the toolpath. You can stop and turn off the spindle to brush off chips...you’re in control, not the CNC. That's TRAKing.

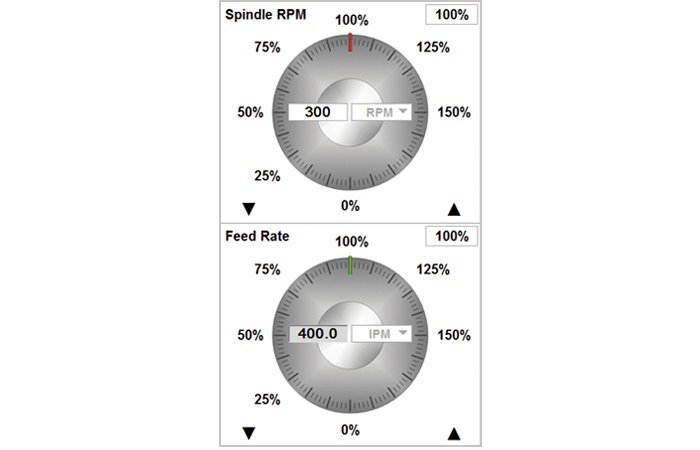

You program spindle speeds and feedrates, but don’t sweat getting them perfect. When you run you have really cool graphical overrides to make adjustments.

Getting into your program to make changes is quick and easy. From any screen, tap PROG. With a few swipes you’re at the event you want to change. Tap the data you want to change and put in the new data. Done. Start machining again.