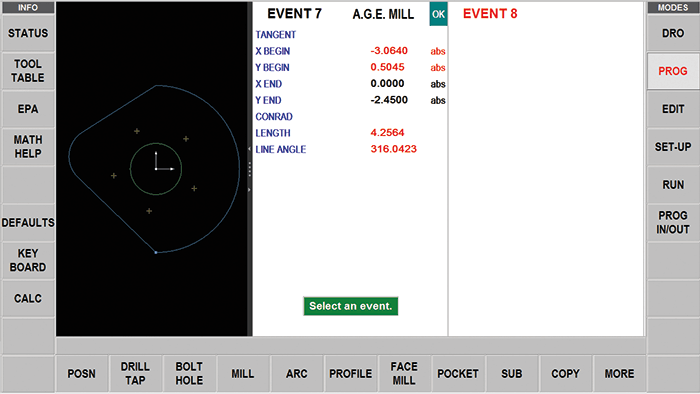

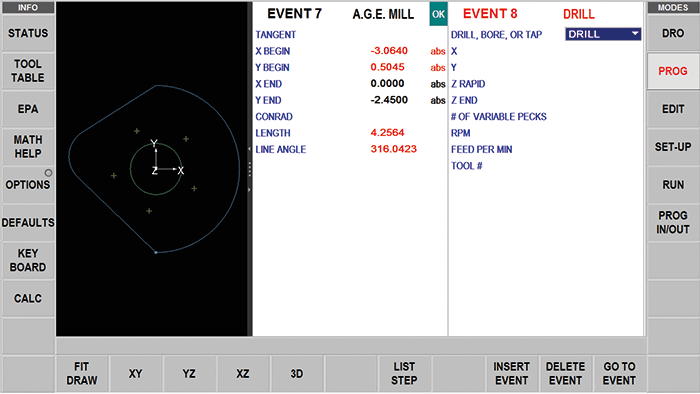

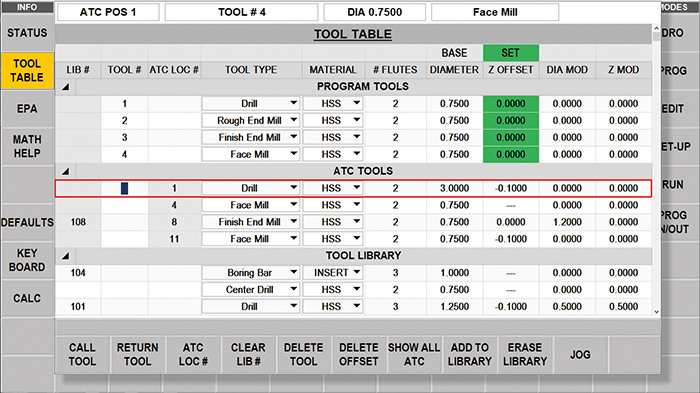

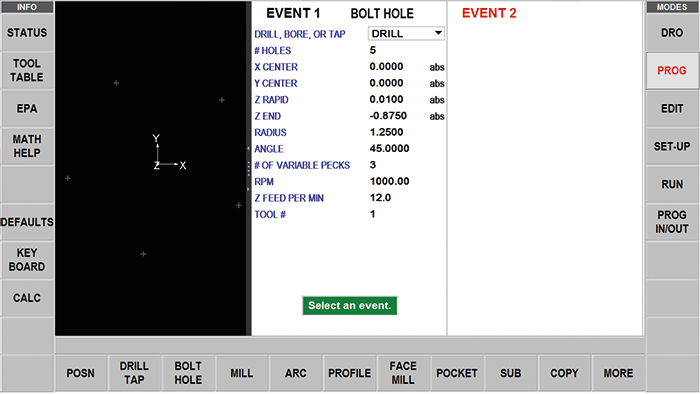

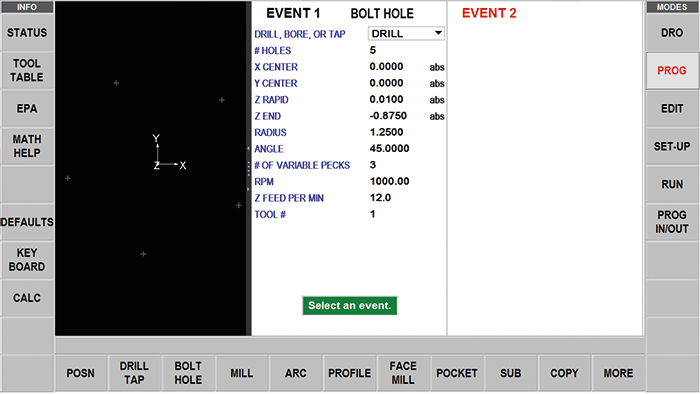

Programming the ProtoTRAK RMX is simply a matter of choosing the geometry from among the canned cycles and then answering the prompts one by one. Everything is in plain language with no codes for you to memorize.

Programming is a simple process of selecting the Event and then describing the geometry from print data. You may program prints or just write simple programs for single operations... it's that easy.

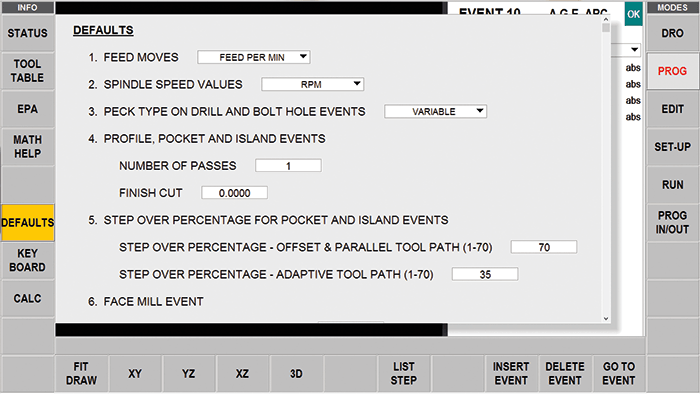

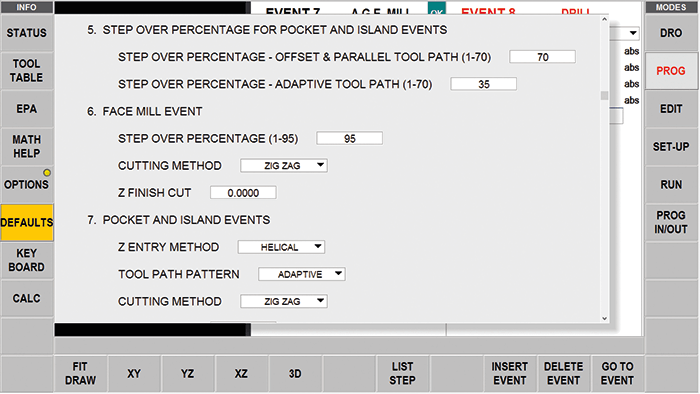

Defaults customize the programming to your style. The prompts will autofill with the choices you make in Defaults, making programming even faster and easier.

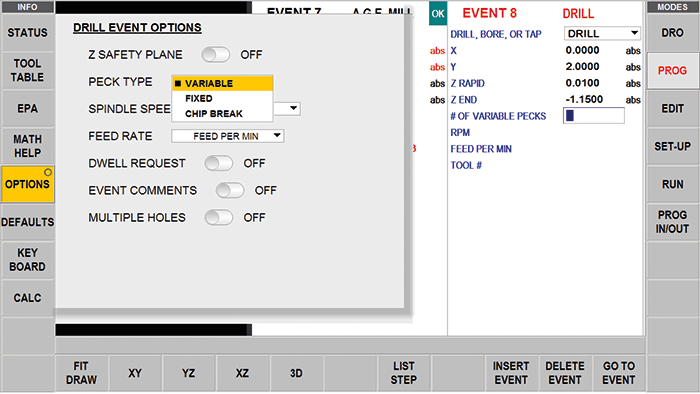

Tap the Options Key while programming the event and you’ll have choices for how the geometry is machined.

There are over 25 canned cycles that make it easy to program even complex shapes right on the shop floor.

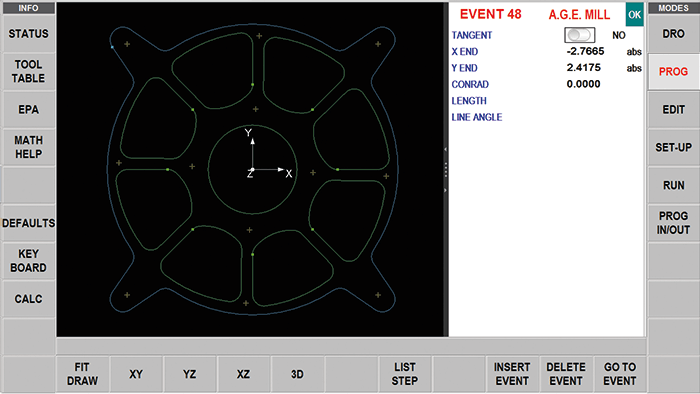

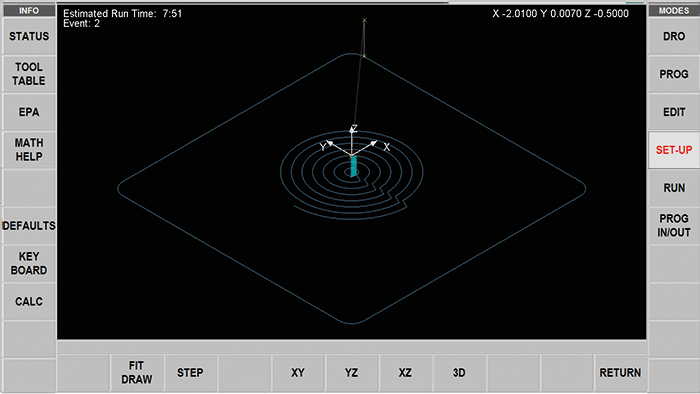

Tool Path gives you a clear idea of where the tool will go.

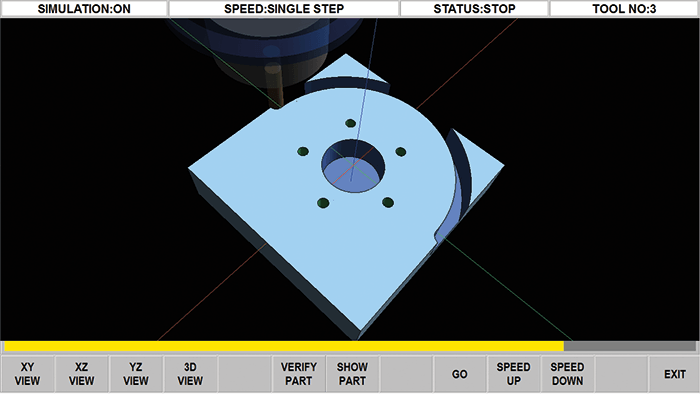

Optional Verify shows you a solid model tool path simulation of what you've programmed.

Adaptive Machining saves machining time and preserves your tools and parts by keeping them cooler throughout the whole process. Other benefits include the ability to engage all or most of the cutter and have a continuous full chip load which will give you a better finish/cut.

The optional Adaptive Tool Path works with Defaults you set up to keep the load constant on the cutter.

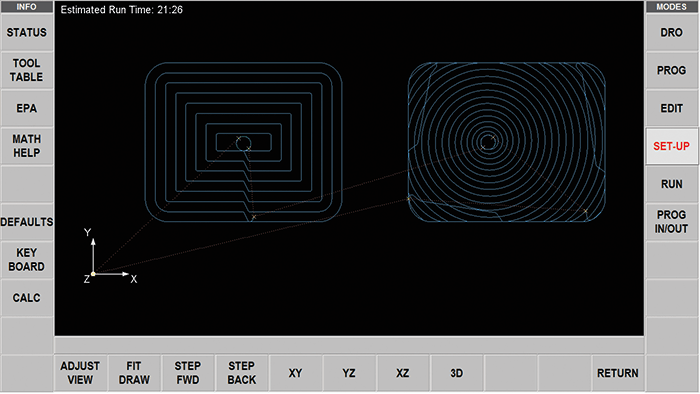

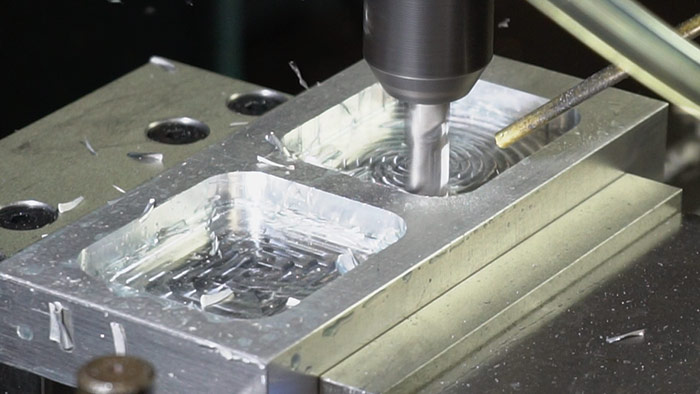

Standard vs. Adaptive Tool Path

Standard vs. Adaptive Tool Path The pocket on the left has a standard tool path. The pocket on the right was machined with Adaptive tool path.

The pocket on the left has a standard tool path. The pocket on the right was machined with Adaptive tool path.