Machinists love to use ProtoTRAKs and it is no wonder. You get the automation you need to be efficient in an elegant interface that is easy to learn and use. At the same time it provides you with the manual capability that you need for so many things you do in a day.

Work manually. Use a 2-axis CNC with manual Z. Set up and run 3-axis CNC. Program it yourself or import a G-code, CAM, CAD or Solid file. It’s all there, waiting for you to make the choices that are best for your work.

Nothing replaces the feel of a manual quill for fine work. The Quill Scale and Ram Position Encoder are coordinated so that you get a single Z Dimension Readout that integrates both.

Whether they are mechanical or Electronic* you can use the handwheels for manual positioning as well as machining. The DRO Mode of the ProtoTRAK RMX CNC makes manual machining more productive with features such as Teach, Power Feed and Center Calculation.

* Electronic handwheels are optional for the DPM RX2 and RX3.

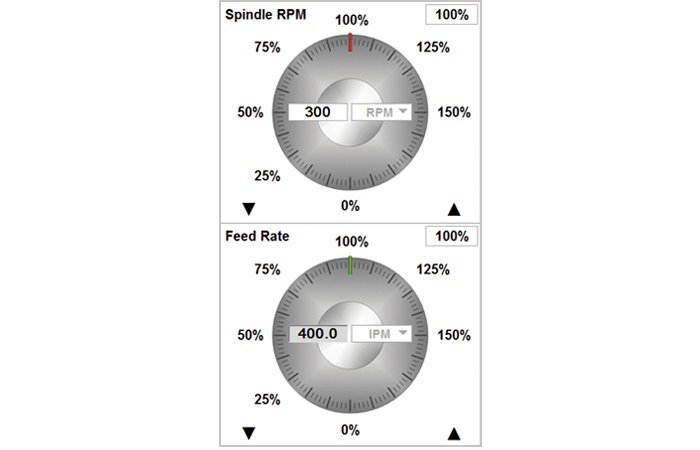

You program spindle speeds and feedrates, but don’t sweat getting them perfect. When you run you have really cool graphical overrides to make adjustments.

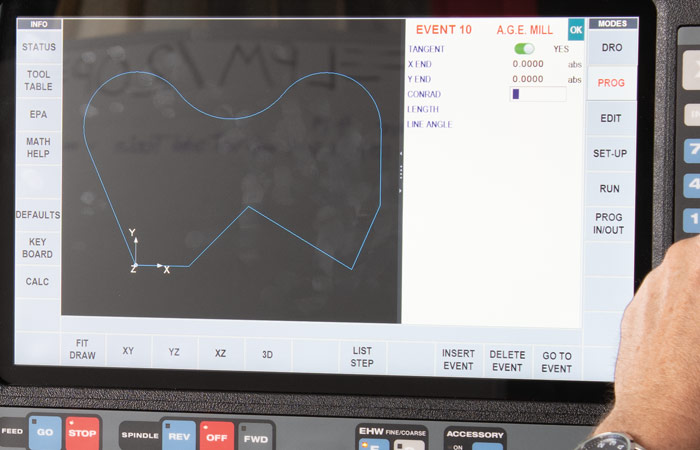

Getting into your program to make changes is quick and easy. From any screen, tap PROG. With a few swipes you’re at the event you want to change. Tap the data you want to change and put in the new data. Done. Start machining again.

We simply cannot say enough about this awesome feature.

Picture this: you’ve written the program. Looked at the toolpath. Everything looks good, so you turn on the spindle and start to run.

But...you have TRAKing. So before you press the GO button you press TRAKing and then grab the handwheels. Talk about being in control! As you crank, the ProtoTRAK runs the program X, Y and Z. You move the feed fast or slow. You can go forward or backward through the toolpath. You can stop and turn off the spindle to move a clamp or brush off chips...you’re in control, not the CNC. That's TRAKing.