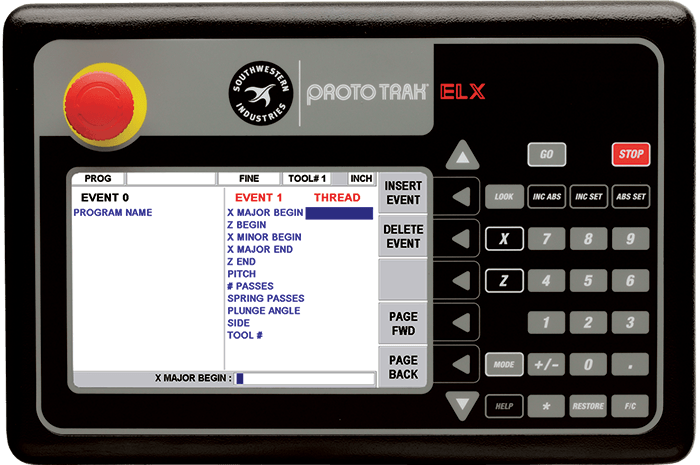

Even if your people have never used a CNC before, they will be able to learn the ProtoTRAK in just a few hours. From the first day you own it, your people will discover that it is easier to make parts with a ProtoTRAK than it is to use manual machining methods. They’ll quickly find, like thousands of machinists before them, that the effort to learn the ProtoTRAK will pay off in job satisfaction.

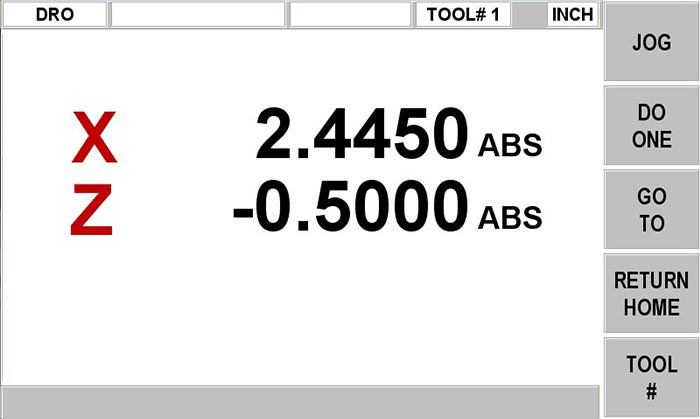

DRO Mode gives you CNC functionality for manual turning work.

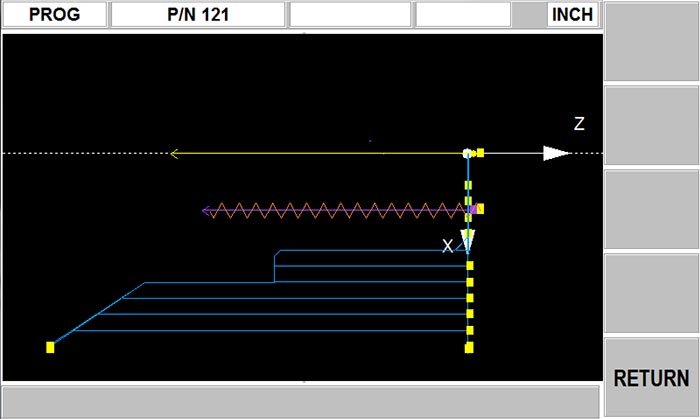

Press the LOOK key while programming to see programmed events with color graphics.

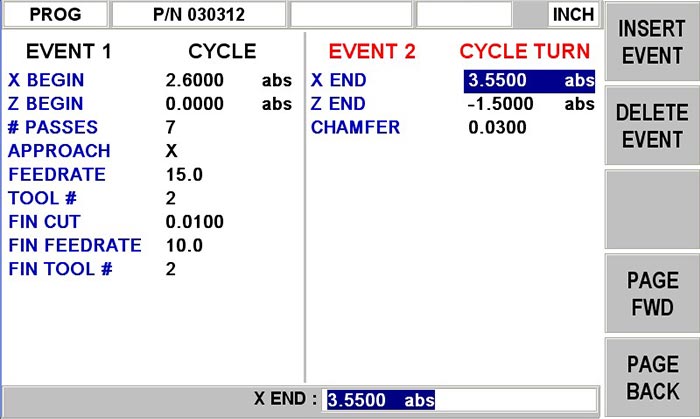

Just program the profile you want and the ELX will program the toolpath to clear the stock for you.

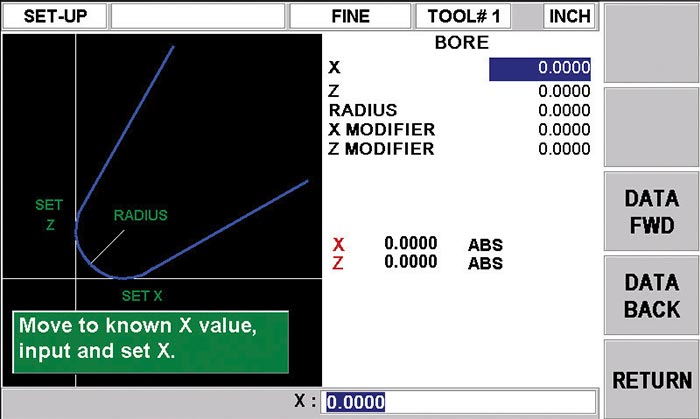

Set tools easily wit hte prompted, graphical interface. Tool data is applied to CNC and manual machining.