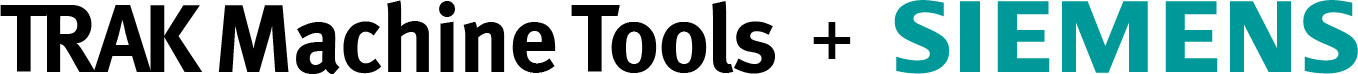

Hardened Box Ways on a Solid Casting provide increased rigidity, better damping, and less vibration for all purpose heavy duty cutting.

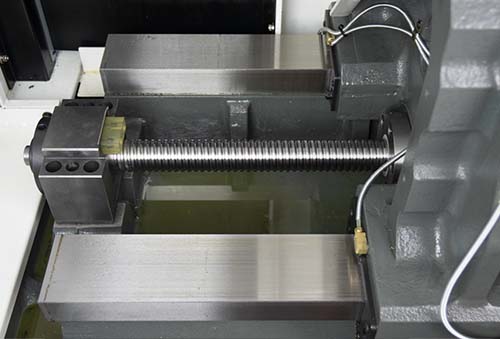

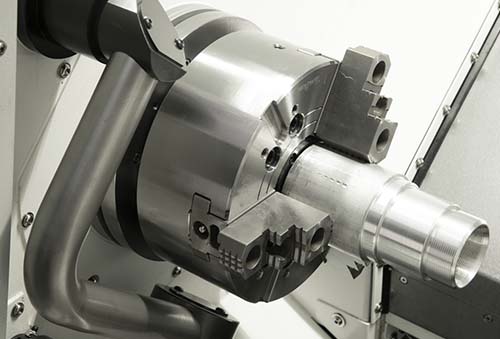

TC820si Only 12-Station Bolt-On Turret that uses block-style clamping to hold 0.75″ shank tooling. Tools may be bolted to either side of the tool pocket to allow for right or left hand tools. Boring bar toolholders accommodate up to 1.5″ shank diameter.

TC820LTYsi Only Industry standard 12-Station BMT45 Live Tooling Turret ( 4500 RPM) offers ample tool clearance, robust connections, and versatility for various tools, including secondary milling operations, with 1/2 index expandable to 24 tools.

Coolant Through Turret efficiently dissipates chips and heat during machining. This greatly enhances cutting performance, accuracy, surface finish and tool life.

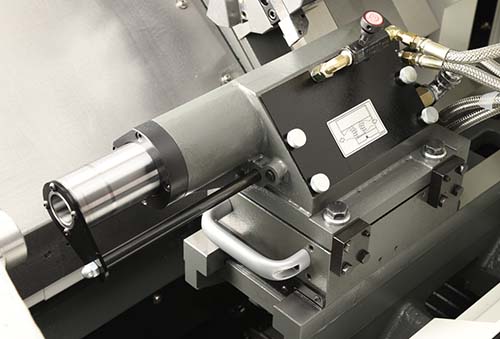

TC820si Only Manual Tailstock with Hydraulic Quill provides additional support for longer workpieces. Quill stroke of 4.13″ with MT4 taper.

TC820LTYsi Only The Hydraulically Clamping Programmable Tailstock & Quill can be automatically positioned along the Z-axis travel and securely clamped in place using built-in subroutines.

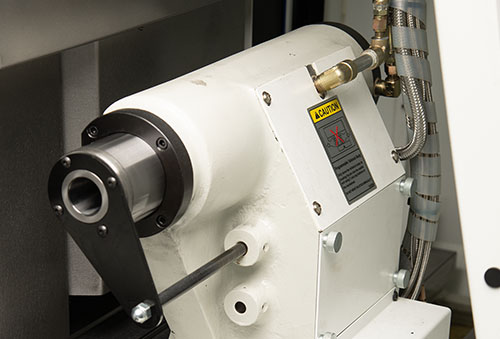

4,000 RPM Spindle with 2.56″ Bar Capacity provides high axial thrust and generates minimal heat. It uses four P4 class angular bearings for optimal support and rigidity.

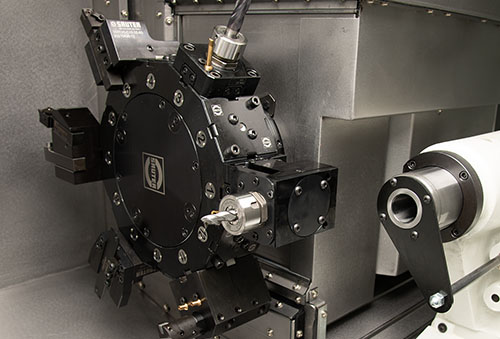

The TC820si is equipped with a manual Tool Setting Arm and Probe.

The TC820LTYsi features an automatic Tool Setting Arm and Probe, which positions itself to touch off tools using a conversational interface or programmed subroutines, automatically detecting tool wear, breakage, and updating offsets.

Direct Drive on X and Z Axes (and Y axis on TC820LTYsi) provide a rigid connection between the motor and the ballscrew for optimum servo control. This enhances accuracy and eliminates backlash.

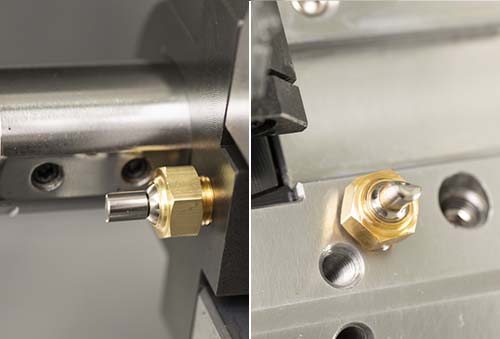

Automatic Lubrication controlled by the CNC system monitors and distributes oil to the box ways and ballscrews to ensure all critical components are always lubricated with the correct amount of oil.

The TC820si is equipped with a 33 gallon tank and pump providing through tool coolant at 30 psi.

The TC820LTYsi has a 50 gallon tank and pump providing through tool coolant at 70 psi.

Chip Conveyor features an internal collection and side discharge system with a high rate of material removal. Chip cart is optional.

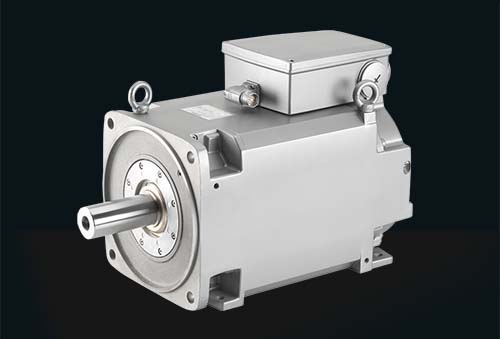

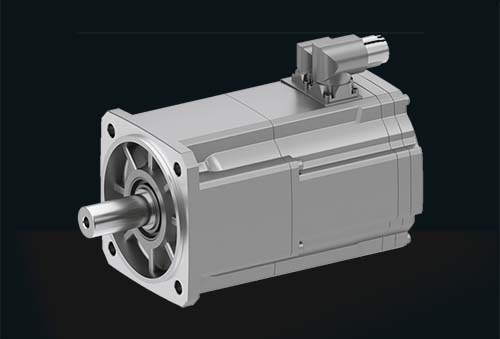

SIMOTICS M-1PH8 Asynchronous Induction Spindle Motor with 14.75 HP continuous — capable of handling extreme duty cycles and short rise times.

High Performance Servo Motors with excellent positioning accuracy.