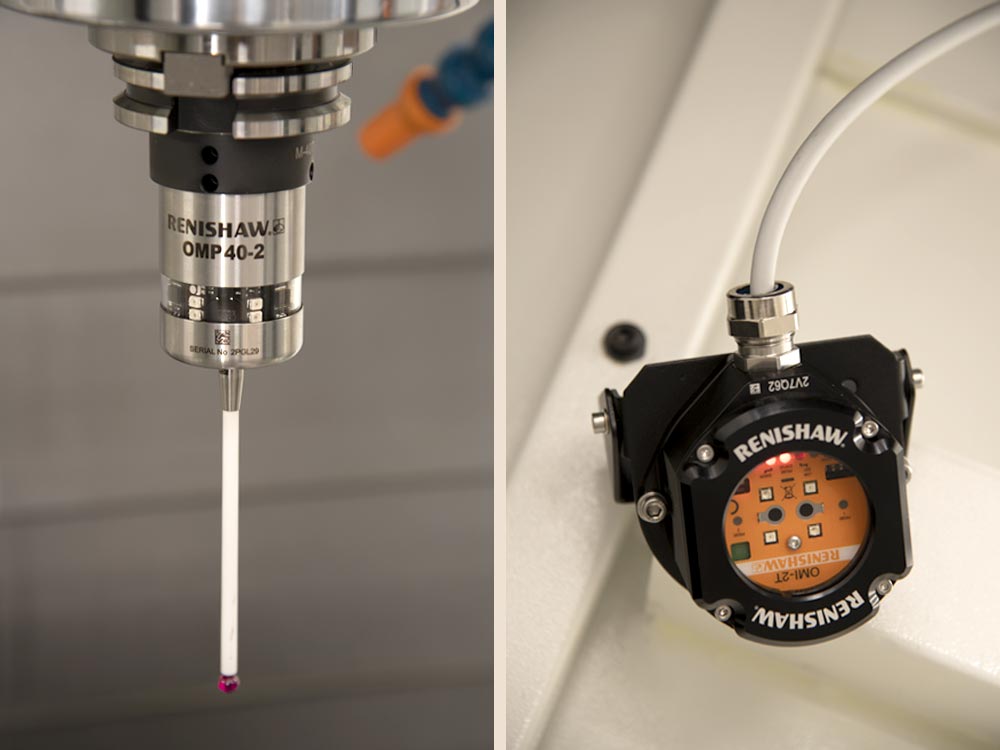

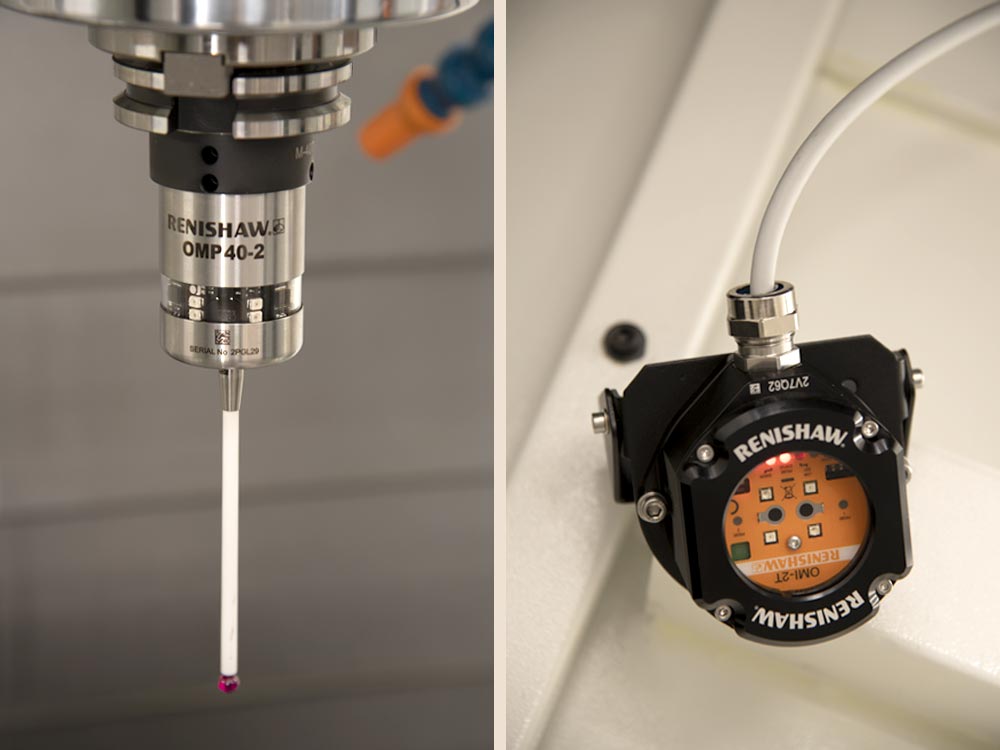

The Renishaw OMP40-2 3D touch-trigger inspection probe is a compact touch probing solution that can be used out-of-the box with the native probing cycles of the SINUMERIK ONE CNC. Using a kinematic mechanism, the OMP40-2 probe is able to achieve a repeatability of 1µm. Optical transmission sends the data to the control without the use of cables. Includes the OMI-2T Optical Receiver.

This option is highly recommended to replace manual edge finders to decrease the amount of time in set-up. The probe may also be integrated into Auto cycles to decrease errors, downtime and scrap.

VIDEO: Part Probing with the SINUMERIK ONE and TRAK VMCsi

The tool probe and part probe can be purchased together as a package.

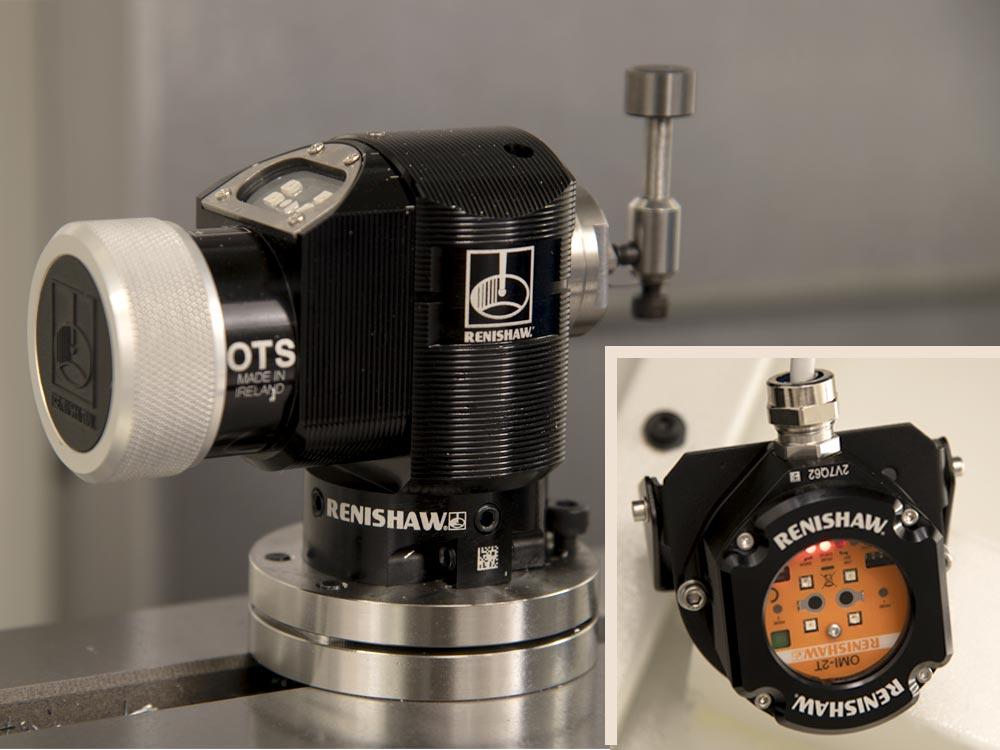

The Renishaw OTS 3D touch-trigger tool setter for automated tool length and diameter measurement can be used out of the box with the native cycles of the SINUMERIK ONE CNC. The kinematic mechanism is capable of achieving a repeatability of 1µm and the use of optical transmission provides a cable-free environment for unrestricted worry-free machine movement. Includes the OMI-2T Optical Receiver.

This option is highly recommended to reduce the amount of time in tool set-up, increase the accuracy of tool table data and enable you to make full use of the powerful tool management capabilities of the SINUMERIK ONE CNC. The OTS Tool setter may also be used within the Auto cycles for in-process tool breakage detection.

The tool probe and part probe can be purchased together as a package.

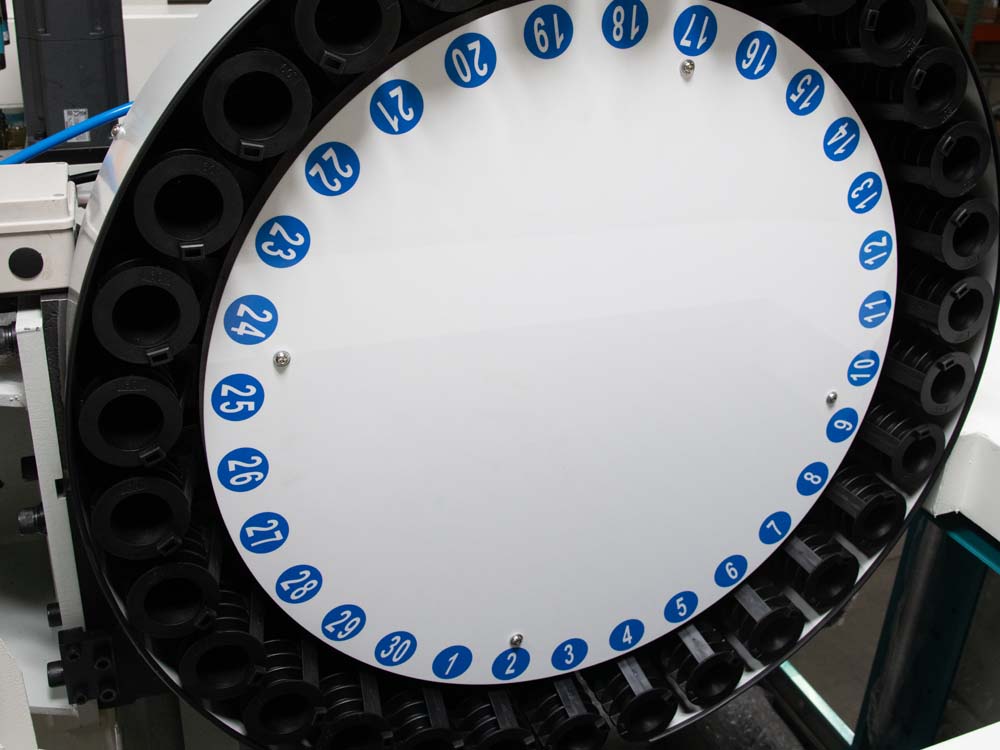

30-station tool magazine features bi-directional tool changes and will accommodate tools up to 11.8″ in length.

40-station tool magazine features bi-directional tool changes and will accommodate tools up to 11.8″ in length.

(Cover removed to show detail.)

The TRAK® 4th axis system for VMCsi series machines provides full control of 4th axis machining through the Siemens SINUMERIK ONE CNC. The system can also be used as an indexer. Includes 8″ three-jaw chuck. Optional tailstock sold separately.

Support for longer workpieces. This option is sold separately.

The electrical cabinet is pre-wired for the optional 4th axis rotary unit. You would want this to have each machine in your shop able to run the 4th axis and then swap the actual rotary unit between them. It also enables the installation of the option on the machine later without a lot of downtime or expense.

Huot® ToolScoot cart and preset tool. Tools not included.

Heavy-duty cart for the set up and transportation of fixtures.

Operated by a button on the control panel or may be programmed.

Set of 24 for CAT 40 tooling and Coolant Through Spindle (CTS).

Set of 24 for BT 40 tooling and Coolant Through Spindle (CTS).

ATC arm is adapted to accept your BT-style tools.

6″ Kurt vise and mounting hardware - model DX6. Opens to 9″.

The USB Memory option consists of an industrial-grade Delkin® Thumb drive. This device is unsurpassed for reliability and speed of file access and is the storage of choice for our own software engineers.

VIDEO: Seamlessly Store Programs with TRAK® USB Memory

Transforms from 480 to 208. Factory mounted in an enclosure on the side of the column. Only available for the VMC7si and VMC10si.

Will command the SINUMERIK ONE to shut down power at the end of a program run. This option is great for untended machining so the machine will shut down after the last part is run. Simply press the APO button on the control panel after the run is initiated.

3D Solid digital twin of your part, faithful in every programmed detail. You can check your program by close inspection of each detail using the touchscreen operation of the 19″ screen of the SINUMERIK ONE.

Advanced Surface is an advanced algorithm that analyzes look ahead and velocity. The software converts points to splines to create a superior toolpath that is processed smoothly through the SINUMERIK ONE run engine.

Best for high-speed roughing applications, but also great for achieving optimal results for general milling. Highly recommended, and part of the One Dynamics Options Package for Job Shops.

A combination of Siemens options that, together, adds internal memory to the SINUMERIK ONE to bring in and integrate large files (such as CAD and CAM).

Open DXF files on the SINUMERIK ONE to easily transfer data into your program. Program faster and reduce errors on programming dimensions. Open and use elements of multiple DXF files in the same program. Works within all the programming methods. Easily command specific features from drawing elements. Set your own part reference independent of the drawing origin.

Run the programmed moves by turning the handwheel. You control the feedrate by moving the Manual Pulse Generator on the control panel and the actual programmed path is moved. Adjust the relationship between the handwheel turns and the feedrate with 4 different resolution settings. Seamlessly go between Handwheel Run and fully automatic CNC run. Great for setups and for confidence making that first part!

Enables you to use a probe within the Auto Mode operation. Insert a probing canned cycle to measure tool wear for the SINUMERIK ONE to apply compensation. You can also measure part features and apply adjustments to either work offsets or tool compensation. The cycle can be programmed to command the control to re-machine features based on the result of the measurement. The probing cycle may be combined with a series of logic statements to give you even more flexibility.

Enables the use of an external memory device for running and editing programs. Allows your memory device to function like an expansion of your internal SINUMERIK ONE memory, without any restrictions on programs, subprograms, commands or even transferring to another machine.

This package contains the following options:

Note: You do not need to buy the MEM‑External option if you buy this package.

This package contains the following options:

Note: You do not need to buy the MEM‑External option if you buy this package.

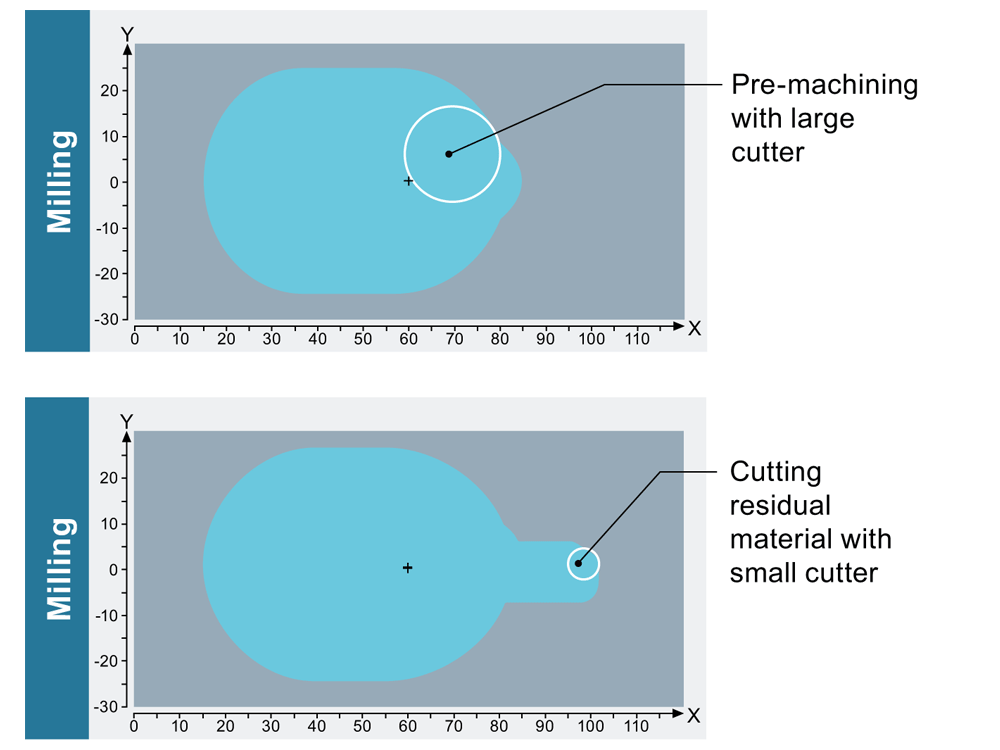

The SINUMERIK ONE automatically recognizes Rest Machining situations. Simply call up the Residual Machining canned cycle, enter a few simple inputs and the control does the rest.

Match the tool to the operation for fastest machining: large tool for hogging, smaller tool for regions the large tool won’t reach. Multiple Residual Machining cycles in the same feature gives you the flexibility to minimize cycle times.

Run MyVirtual Machine gives you rich simulations offline. You can program and optimize your jobs while your machine is running a different job.

ARTICLE: Run MyVirtual Machine — The Digital Twin of the Machine Application

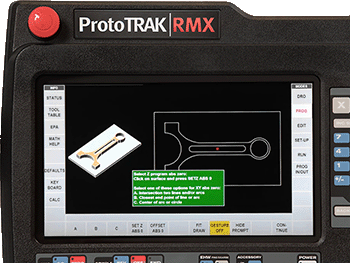

True conversational programming you can do right on the shop floor. Write complete part programs or insert a feature within another program. With guidance from Animated Elements, Tool Tips, Dynamic Graphics, Canned Cycles and Context-Sensitive Help to guide you can create programs with ease. You won’t have to go back to the person who programmed the part to fix or add to your program.

3D Solid model graphics real time while running a program. It is a great way to check the progress of your job, especially when you are running a lot of coolant.

Top Surface is an advanced algorithm that analyzes look ahead and velocity. The software converts points to splines to create a superior toolpath that is processed smoothly through the SINUMERIK ONE run engine.

This software will actually fix problems with the imported CAM data, detecting gaps in the points distribution that will result in jerking or hesitations as the program runs. This option is best for high-speed finishing in mold making where the very best surface quality is required. Part of the One Dynamics Options Package for Surfacing.

You are able to choose the between maximizing Machining Velocity, Surface Quality and Dimensional Accuracy. For example, turning on the “Smoothing” function in Top Surface will greatly increase part surface quality but may possibly slow the machining. This advanced software puts the trade-offs into your hands – where it belongs.

Wraps a 2D shape around a cylinder, enabling you to program features onto a cylinder using the 4th Axis option of your VMCsi machine.

The OPC UA (Unified Architecture) standard is particularly suitable for data exchange across different levels as it is independent from specific operating systems, has secure transfer procedures and better semantic description of the data.

OPC UA not only makes data available, but also provides information about the data (e.g. data types). This enables machine-interpretable access to the data.

The TRAK MTConnect option enables customers to add MTConnect functionality quickly and easily to their machines, so that machine data can be collected using the standard MTConnect protocol.

3rd party software not included.

VIDEO: MTConnect® Option Overview

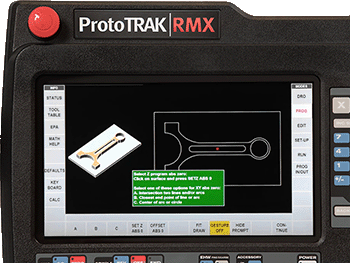

Renishaw® OMP40-2 Inspection Probe and OMI-2T Optical Receiver

The OMP40-2 Inspection Probe is a compact probing solution that uses a kinematic mechanism able to achieve a repeatability of 1 µm. The probe interfaces with the OMI-2T Optical Receiver that mounts inside the TMC. Both devices are included in the Part Probing option.

You use the Probe with the Electronic Handwheels as a productive way to replace edge finders for touching off parts and fixtures. The option works in the DRO Mode of the ProtoTRAK RMX CNC to set offsets using the ABS SET and INC SET features. You can also use it with the Center feature to easily calculate line lengths and diameters of circles.

The Haimer® Universal 3D Sensor lets you quickly find edges in X and Y relative to the center of the spindle. Unlike a standard edge finder, it is unnecessary to allow for the diameter of the probe. Simply bring the dial to zero, and you are finished. The sensor also allows you to find the part in Z.

The feel of manual control of real handwheels, but our electronic handwheels bring the power of the CNC to your fingertips through features such as TRAKing and DO ONE.

The TRAK® 4th axis system for Toolroom Machining Centers provides full control of 4th axis machining and engraving through the ProtoTRAK RMX CNC. The system can also be used as an indexer. Includes 8″ three-jaw chuck. Optional tailstock sold separately.

Support for longer workpieces. This option is sold separately.

The electrical cabinet is pre-wired for the optional 4th axis rotary unit. You would want this to have each machine in your shop able to run the 4th axis and then swap the actual rotary unit between them. It also enables the installation of the option on the machine later without a lot of downtime or expense.

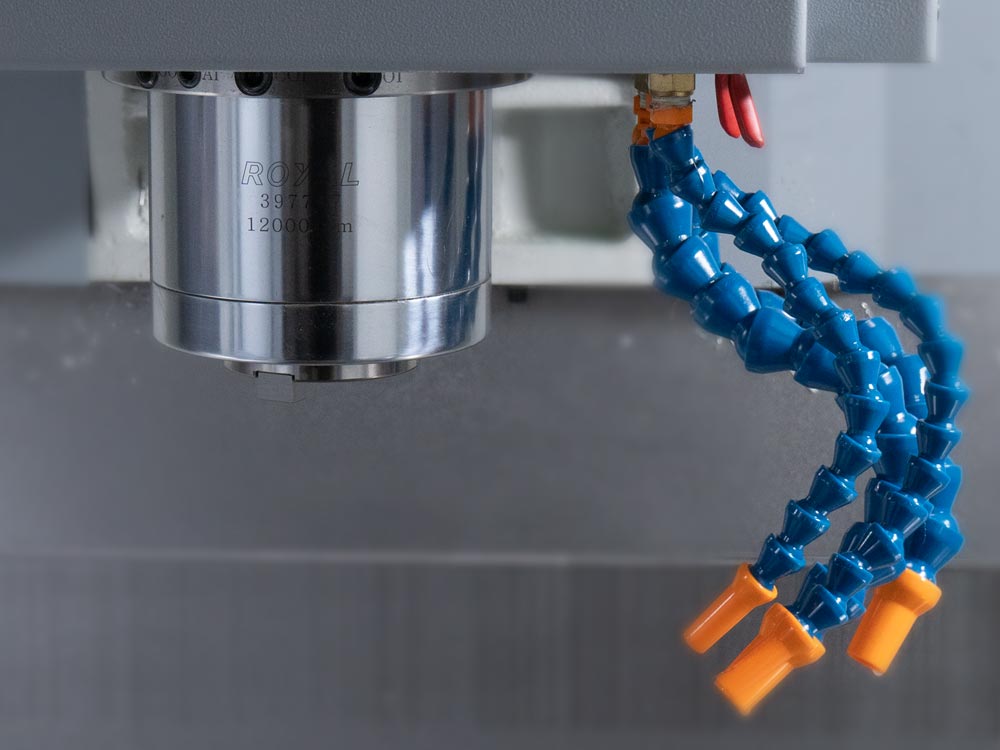

The TRAK CTS system provides pressurized coolant to remove chips during drilling and tapping work. Compared to flood coolant, the CTS option can increase tool life, allow for higher spindle speeds and a corresponding reduction of cycle times, and allow for better surface finishes.

The optional 12,000 RPM spindle features ceramic bearings, and a spindle cooler to minimize temperature rise when running for long periods of time.

A hand-held switch to stop and continue program run. Available for purchase at our service parts website: Remote Stop/Go Switch

Huot® ToolScoot cart and preset tool. Tools not included.

Heavy-duty cart for the set up and transportation of fixtures.

Set of 16. Includes mounting hardware.

For CAT40 tooling. Set of 16.

6″ Kurt vise and mounting hardware - model DX6. Opens to 9″.

The USB Memory option consists of an industrial-grade Delkin® Thumb drive. This device is unsurpassed for reliability and speed of file access and is the storage of choice for our own software engineers.

VIDEO: Seamlessly Store Programs with TRAK® USB Memory

Clear Off allows for the removal of part material from the outside in, leaving only the bosses and profiles you want. This option is easily programmed at the machine, and works with both DXF and Parasolid models.

VIDEO: Clear Off Programming Demo | ProtoTRAK RMX CNC

Write, save and then run programs with RX Canned Cycle Events on Legacy ProtoTRAK controls in either .CAM Events or .GCD format.

VIDEO: Learn to Install ProtoTRAK Offline Software

The TRAK MTConnect option enables customers to add MTConnect functionality quickly and easily to their machines, so that machine data can be collected using the standard MTConnect protocol.

3rd party software not included.

VIDEO: MTConnect® Option Overview

Enables programming and control of:

30 taper. Set of 8 knobs.

Tools and tool presetting gage are not included. Actual cart may vary slightly from image shown.

30 Taper

Precision 18″ x 15″ plate with primary liners. Made of aluminum tooling plate that resists warping.

Includes precision plate, liners, fence, stop and hardware.

Includes magnetic base with 1″, 2″, and 3″ extensions.

BT30, eight pieces, assorted sizes.

Available in sets of four.

High precision version for use with primary locating holes. Lower precision version for use with secondary locating holes.

Modified for the TRAK VMC2 and TRAK 2op (recommended).

The USB Memory option consists of an industrial-grade Delkin® Thumb drive. This device is unsurpassed for reliability and speed of file access and is the storage of choice for our own software engineers.

VIDEO: Seamlessly Store Programs with TRAK® USB Memory

Clear Off allows for the removal of part material from the outside in, leaving only the bosses and profiles you want. This option is easily programmed at the machine, and works with both DXF and Parasolid models.

VIDEO: Clear Off Programming Demo | ProtoTRAK RMX CNC

Write, save and then run programs with RX Canned Cycle Events on Legacy ProtoTRAK controls in either .CAM Events or .GCD format.

The TRAK MTConnect option enables customers to add MTConnect functionality quickly and easily to their machines, so that machine data can be collected using the standard MTConnect protocol.

3rd party software not included.

VIDEO: MTConnect® Option Overview