Productos TRAK

TRAK Machine Tools ofrece una amplia gama de soluciones innovadoras en máquinas herramienta diseñadas para mejorar la productividad y precisión en las operaciones de mecanizado. Además de nuestros reconocidos CNC ProtoTRAK® con programación conversacional fácil de usar, ofrecemos máquinas de producción equipadas con el avanzado CNC SINUMERIK ONE® para un rendimiento y eficiencia superiores.

Nuestra línea incluye fresadoras de alto rendimiento, tornos y fresadoras de bancada, que brindan versatilidad y confiabilidad para maquinistas, talleres y plantas de fabricación. Ya sea que esté actualizando su taller o ampliando sus capacidades de producción, TRAK Machine Tools ofrece soluciones de precisión respaldadas por experiencia y soporte líderes en la industria.

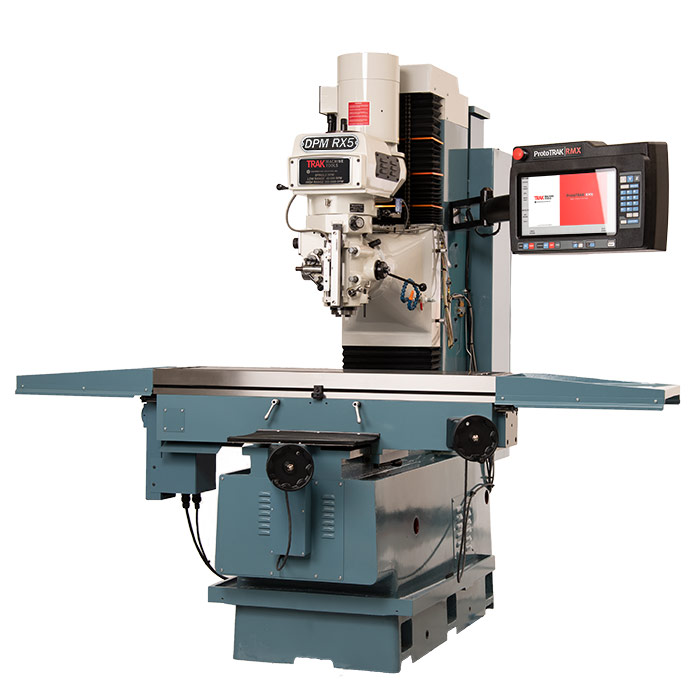

DPMRX Series Bed Mills

The TRAK DPMRX Series Bed Mills feature the ProtoTRAK RMX CNC for easy operation and precision machining. Built for versatility, they handle both manual and CNC work with ease.

-

Tamaño de la Mesa:

1,930.40 mm (76″) x 355.60 mm (14″)

-

Desplazamiento:

1,524 mm (60″) x 584.20 mm (23″) x 615.95 mm (24.25″)

-

Motor del Husillo:

7.5 HP de Trabajo Continuo

-

Conicidad del Portaherramientas:

Cono 40

-

Tamaño de la Mesa:

1,270 mm (50") x 304.80 mm (12")

-

Desplazamiento:

1,016 mm (40") x 508 mm (20") x 655.57 mm (25.81")

-

Motor del Husillo:

5 HP de Trabajo Continuo

-

Conicidad del Portaherramientas:

Cono 40

-

Tamaño de la Mesa:

1,270 mm (50") x 254 mm (10")

-

Desplazamiento:

800.10 mm (31.5") x 431.80 mm (17") x 655.57 mm (25.81")

-

Motor del Husillo:

5 HP de Trabajo Continuo

-

Conicidad del Portaherramientas:

Cono 40

-

Tamaño de la Mesa:

1,244.60 mm (49″) x 228.6 mm (9″)

-

Desplazamiento:

787.40 mm (31.75″) x 406.40 mm (16″) X 590.5 mm (23.25″)

-

Motor del Husillo:

3 HP de Trabajo Continuo

-

Conicidad del Portaherramientas:

R8

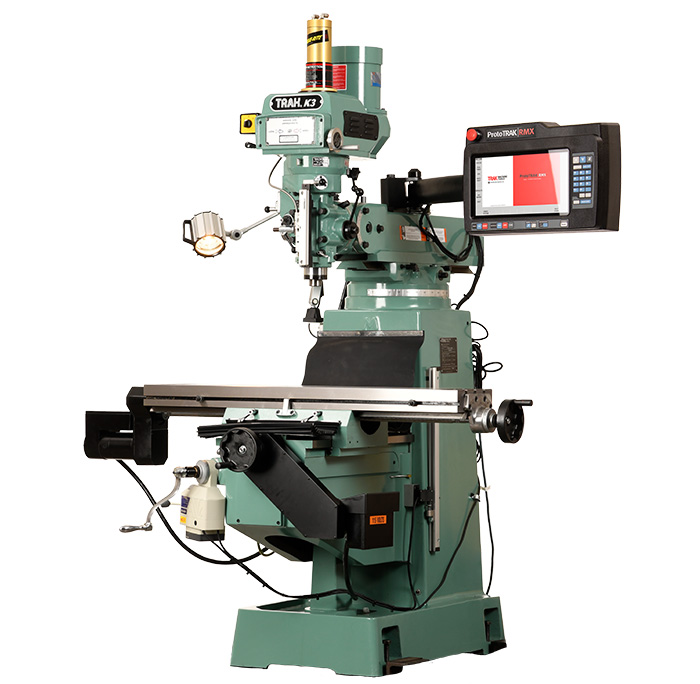

K3 CNC Knee Mills

TRAK Knee Mills offer the flexibility of manual or CNC operation, featuring real handwheels for manual control and the option of ProtoTRAK RMX or KMX CNC systems. These machines are ideal for machinists seeking versatile milling solutions.

-

Tamaño de la Mesa:

254 mm x 1,270 mm

-

Ranuras en T:

3 x 15.875 mm x 63.50 mm

-

Desplazamiento de la Mesa:

812.8 mm

-

Saddle Travel:

406.4 mm

-

Knee Travel:

406.4 mm

-

Conicidad del Portaherramientas:

R8

-

Motor del Husillo - Vari-Speed:

3 HP

TRLRX Series Lathes

TRAK Toolroom Lathes offer both manual and CNC operations, featuring the ProtoTRAK RLX CNC for user-friendly control. With programmable spindle speeds and optional turrets for automated tool changes, they enhance productivity and flexibility in turning tasks.

-

Diámetro Admitido Sobre las Guías de la Bancada:

838.2 mm

-

Distancia Entre los Centros:

2,997.2 mm

-

Diámetro de Paso de Barra A Través del Husillo:

160.02 mm

-

Rango de Velocidades del Husillo (RPM):

20 - 415, 40 - 1,300

-

Diámetro Admitido Sobre las Guías de la Bancada:

355.6 mm (33″)

-

Distancia Entre los Centros:

1,524mm (60")

-

Diámetro de Paso de Barra A Través del Husillo:

160.02mm (6.3")

-

Rango de Velocidades del Husillo (RPM):

20 - 415, 40 - 1,300

-

Diámetro Admitido Sobre las Guías de la Bancada:

609.6 mm (24")

-

Distancia Entre los Centros:

1,778 mm (70")

-

Diámetro de Paso de Barra A Través del Husillo:

103.89 mm (4.09")

-

Rango de Velocidades del Husillo (RPM):

40 - 670, 100 - 1,800

-

Diámetro Admitido Sobre las Guías de la Bancada:

457.2 mm (18")

-

Distancia Entre los Centros:

1,143 mm (45")

-

Diámetro de Paso de Barra A Través del Husillo:

59.94 mm (2.36")

-

Rango de Velocidades del Husillo (RPM):

80 - 850, 250 - 2,500

-

Diámetro Admitido Sobre las Guías de la Bancada:

406.4 mm (16″)

-

Distancia Entre los Centros:

762 mm (30″)

-

Diámetro de Paso de Barra A Través del Husillo:

39.88 mm (1.57″)

-

Rango de Velocidades del Husillo (RPM):

150 - 4,000

-

Diámetro Admitido Sobre las Guías de la Bancada:

406.4 mm (16″)

-

Distancia Entre los Centros:

762 mm (30″)

-

Diámetro de Paso de Barra A Través del Husillo:

53.85mm (2.12″)

-

Rango de Velocidades del Husillo (RPM):

150 - 2,500

Toolroom Machining Centers

-

Tamaño de la Mesa:

1,600 x 600 mm

-

Desplazamiento:

1,524 x 685.8 x 635 mm

-

Disposición en Piso (Huella):

399.99 x 367.69 cm

-

Caballos de Fuerza:

22.5/15

-

Tamaño de la Mesa:

1,300 x 600 mm

-

Desplazamiento:

1,270 x 685.8 x 635 mm

-

Disposición en Piso (Huella):

340 x 367.69 cm

-

Caballos de Fuerza:

22.5/15

-

Tamaño de la Mesa:

1,120 x 500 mm

-

Desplazamiento:

1,035 x 508 x 508 mm

-

Disposición en Piso (Huella):

281.94 x 342.90 cm

-

Caballos de Fuerza:

15/10

-

Tamaño de la Mesa:

900 x 500 mm

-

Desplazamiento:

762 x 508 x 508 mm

-

Disposición en Piso (Huella):

246.38 x 342.90 cm

-

Caballos de Fuerza:

15/10

-

Tamaño de la Mesa:

700 x 400 mm

-

Desplazamiento:

508 x 406.4 x 508 mm

-

Disposición en Piso (Huella):

215.9 x 328.30 cm

-

Caballos de Fuerza:

15/10

Vertical Machining Centers

TRAK Toolroom Machining Centers, equipped with the ProtoTRAK RMX CNC, offer unmatched flexibility for both manual and CNC operations. Complementing them, the TRAK VMCsi Vertical Machining Centers feature the advanced SINUMERIK ONE CNC, providing high-performance solutions for demanding production environments. Both series deliver precision and efficiency to meet diverse machining needs.

-

Tamaño de la Mesa:

1,599.94 mm (62.99″) x 599.94 mm (23.62″)

-

Desplazamiento:

1524 mm (60″) x 698.5 mm (27.5″) x 635 mm (25″)

-

Huella en Piso:

4,572 mm (180″) x 3213.10 mm (126.50″)

-

Caballos de Fuerza:

67/26.8

-

Tamaño de la Mesa:

1,299.97 mm (51.18″) x 599.94 mm (23.62″)

-

Desplazamiento:

1,270 mm (50″) x 698.5 mm (27.5″) x 635 mm (25″)

-

Huella en Piso:

4273.55 mm (168.25″) x 3213.1 mm (126.50″)

-

Caballos de Fuerza:

67/26.8

-

Tamaño de la Mesa:

1,119.88 mm (44.09″) x 500.12 (19.69″)

-

Desplazamiento:

1016 mm (40″) x 508 mm (20″) x 508 mm (20″)

-

Huella en Piso:

3,657.6 mm (144″) x 2,844.8 mm (112″)

-

Caballos de Fuerza:

41.5/20

-

Tamaño de la Mesa:

899.92 (35.43″) x 500.12 (19.69″)

-

Desplazamiento:

762 mm (30″) x 508 mm ( 20″) x 508 mm (20″)

-

Huella en Piso:

3,657.6 mm (144″) x 2,844.8 mm (112″)

-

Caballos de Fuerza:

41.5/20

Turning Centers

TRAK TCsi Turning Centers are high-precision CNC production lathes featuring the advanced SINUMERIK ONE CNC control. Designed for efficient setups and versatile machining, they offer integrated spindles and robust construction to meet demanding production requirements.

-

Diámetro Admitido:

304.80 mm

-

Longitud Máxima de Torneado:

279.40 mm

-

Número de Herramientas:

8 Estaciones

-

Altura de Centros:

1,049.02 mm

-

Longitud Máxima de Torneado:

508 mm

-

Número de Herramientas:

12 Estaciones (Sujeción por Tornillos)

-

Altura de Centros:

1,201.42 mm

-

Longitud Máxima de Torneado:

489.96 mm

-

Número de Herramientas:

12 Estaciones de Herramientas Motorizadas (BMT45)

ProtoTRAK CNC Retrofits

TRAK Machine Tools offers ProtoTRAK CNC retrofits to upgrade manual knee-type milling machines, such as Bridgeport models, enhancing productivity with user-friendly controls and advanced features. Options include the ProtoTRAK RMX and KMX CNCs, both available in 2 or 3-axis configurations, designed to improve efficiency in various machining tasks.

ProtoTRAK CNC Upgrades

TRAK Machine Tools offers ProtoTRAK CNC upgrades to enhance the performance of older models like the M2, M3, MX2, MX3, AGE2, and AGE3. Customers can choose between the ProtoTRAK RMX CNC, which provides powerful features for manual milling and enhanced assistance, and the ProtoTRAK KMX CNC, known for its ease of use and improved Auto Geometry Engine®. Both upgrades aim to improve productivity while maintaining a user-friendly interface.